Our quality control process

At ZMlash, quality control is an integral part of our manufacturing process. We have implemented a stringent quality control system to ensure that every lash product meets our high standards.

1. Material inspection

We start by carefully evaluating the materials for our eyelashes. Our quality control team ensures that only the finest materials, like premium Korean PBT fiber

2. Production line checks

Our skilled team closely monitors the production line, inspecting each eyelash to ensure consistent length, thickness, and curl throughout the crafting process.

3. Visual & tactile

Our quality control team thoroughly inspects each lash, checking for defects. They also assess softness, flexibility, and overall quality to ensure the highest standards are met.

4. Packaging inspection

Our quality control team conducts a final inspection to ensure the packaging is intact, clean, and correctly labeled. This guarantees that your orders are well-protected and arrive in perfect condition.

Only top-grade materials and ingredients are chosen at ZMLASHEE

We prioritize quality and are committed to offering our customers the finest products. All our lash extensions are crafted using top-grade PBT materials imported from Korea, renowned for their superior quality. These materials are meticulously chosen to ensure a soft texture and a beautiful, glossy sheen.

Faux mink

We use premium faux mink materials known for their softness, natural look, and lightweight feel. These lashes offer a luxurious appearance while ensuring exceptional comfort for the wearer.

Silk fiber

Silk fiber lashes are made from high-quality synthetic silk, offering a soft, lightweight feel. Perfect for clients with sensitive eyes, they provide exceptional comfort and a refined, elegant look.

Human hair

Our diy cluster lash, made from premium human hair, provide an authentic look and feel. They seamlessly blend with natural lashes, delivering a flawless and effortlessly natural appearance.

Cuticle-Intact hair

This material maintains the natural structure and integrity of the hair, ensuring enhanced durability and a flawlessly seamless appearance.

Biodegradable materials

We are dedicated to sustainability, offering biodegradable lash options that minimize environmental impact while maintaining high quality and performance.

Look at our expertise

We believe technology is key to ensuring quality. With years of experience, our craftsmen have perfected techniques and possess the expertise to deliver meticulous craftsmanship in every lash product.

Triangle Pyramid Fibers

Laser-cut eyelashes offer a greater surface area for bond contact, resulting in a 30% increase in wearing time.

Laser Cutting

Lashes are cut with a ring laser, providing a larger surface area for bond contact, which increases wear time by 50%.

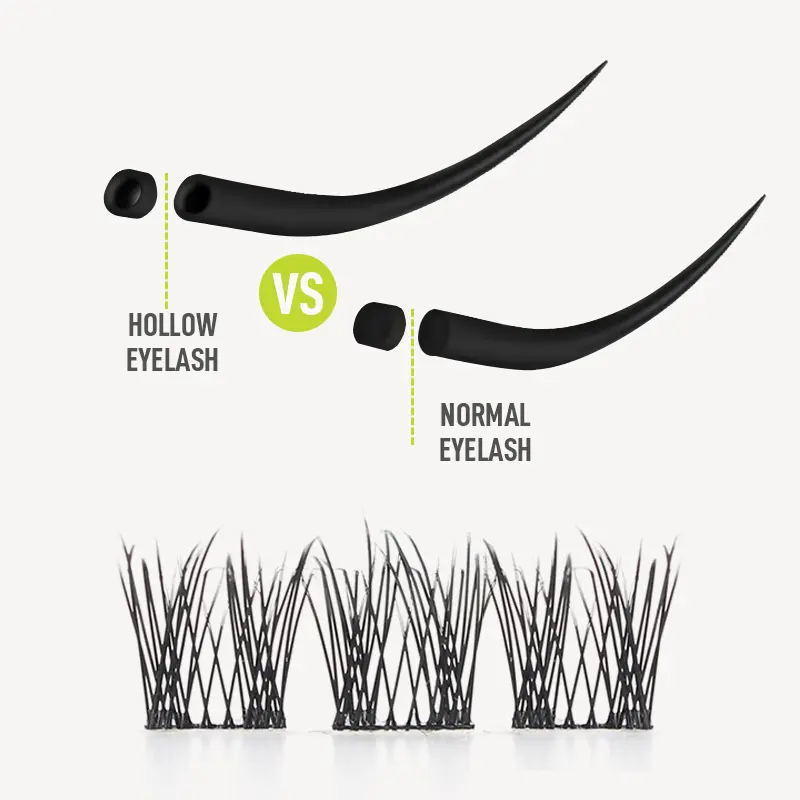

Hollow Fibers

Hollow eyelash material is used to reduce the weight of the lashes by 30%, making them lighter to wear while enhancing their durability for longer-lasting use.

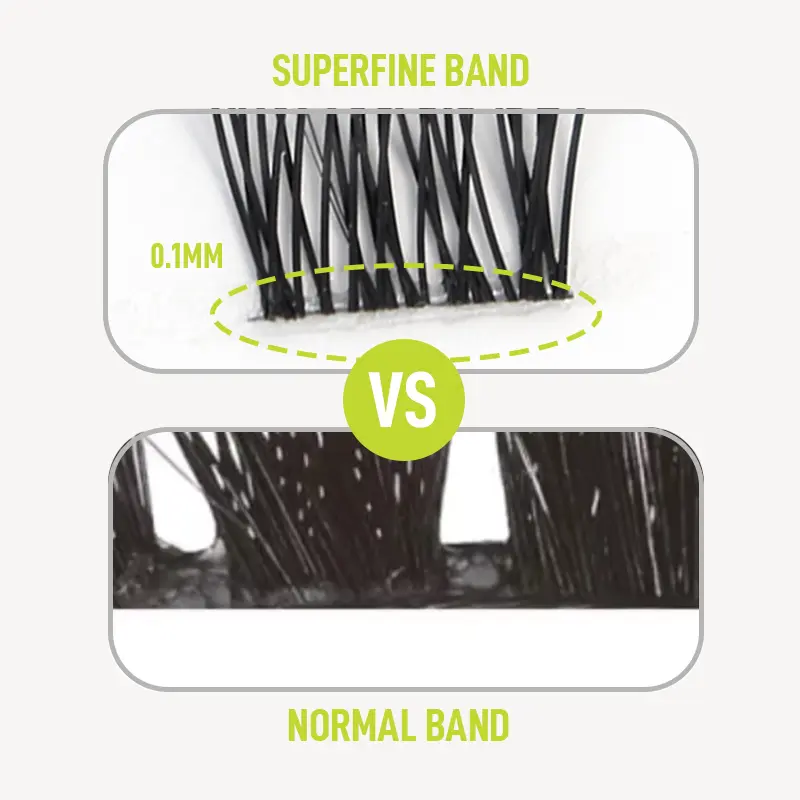

Super Fine Band

Using patented technology, the superfine band measures just 0.1mm, offering a seamless and lightweight feel for maximum comfort and a natural look.

Blending fiber

Flat lashes paired with classic lashes create a messy, fluffy look, combining volume and texture for a natural yet voluminous appearance.

Super soft band

Unlike regular eyelashes, this eyelash band is softer and conforms better to the natural shape of the eyes, ensuring a comfortable fit and a more natural appearance.

Super bond & selaer

After 2 years of development, our lash bond & seal, used together, lasts up to 15 days. It is waterproof, sweat-resistant, and the first choice for leading brands.

Super soft fibers

Our thorough testing process guarantees the quality and consistency

1. Texture and softness assessment

Our team inspects each lash for any rough or coarse areas that could impact comfort and the natural look once applied.

2. Durability testing

This includes simulated activities like rubbing, brushing, and exposure to water. During these tests, the lash extensions must retain their shape, curl, and overall integrity, ensuring durability and long-lasting performance.

3. Curl retention evaluation

We assess the curl retention of our lash extensions over a set period, monitoring them to ensure they maintain their desired curl without drooping or losing shape, guaranteeing a flawless look that lasts.

4. Tensile strength assessment

This test applies controlled pressure to the lash extension to evaluate its maximum strength, ensuring it meets our rigorous quality standards for durability and performance.

5. Final visual inspection

Our quality control team carefully inspects each lash for defects like uneven lengths, inconsistent curls, or irregular shapes. The lashes are evenly placed on the adhesive band, ensuring they meet ZMLASHEE’s standards for density and consistency in a single lash line.

6. Debris check

Throughout the manufacturing process, we take special precautions to prevent debris or particles from contaminating the lash tray. This ensures that our lash extensions stay free from impurities, providing our customers with a clean and flawless product.

How we inspect lash products before shipping

Accuracy

We carefully inspect the packaging materials to ensure they are free from damages, defects, or irregularities. This includes checking for secure sealing and intact labels. Our team also verifies that all essential details, such as product labels, barcodes, and batch numbers, are correctly printed on the packaging.

Impurity inspection

Before shipping, our delivery department conducts an impurity inspection to ensure that each product is clean, tidy, and free from contamination. All testing and packaging processes are carried out in a dust-free workshop. This commitment to quality is our ultimate goal for building lasting, reliable partnerships.

Confirm and pack

After the final quality inspection, our sales manager will confirm the order details with you and invite you to review the product via video. Typically, we include a percentage of extra products in the order to compensate for any potential damage during transportation.we will select the best logistics company for you

FAQs about ZMlashee quality control process

1. How does Zmlashee ensure the quality of its lash products?

ZMlash guarantees quality with strict quality control at every production stage. We carefully select premium materials, conduct detailed inspections, and follow rigorous manufacturing processes to ensure consistent excellence in each product.

2. Are ZM lash lash products tested for durability and curl retention?

Yes, ZMlash lash products undergo extensive testing to assess their durability, curl retention, and overall quality. We simulate various environmental conditions to evaluate their performance, ensuring they consistently meet our high standards.

3. How does ZMlash handle defective lash products?

In the rare case of a defective lash product, ZMlash offers a straightforward return and refund policy. We take prompt action to resolve any issues and ensure complete customer satisfaction.

4. Are ZMlash lash products safe for use?

Yes, all ZMlash lash products are crafted with safe materials and undergo rigorous testing to ensure they meet safety standards. We prioritize the well-being of our customers and are committed to delivering reliable, safe lash products.

5. Does ZM lash have any quality certifications?

Yes, ZMlash holds several quality certifications, including ISO 9001, ISO 14001, MSDS, and SGS. These certifications affirm our commitment to maintaining the highest quality standards in both our lash products and operational processes.

Flexible Private Label Cooperation Plans

beginner

First-time brand starters-

300+ pieces (average)

-

Sample shipped in 3 days

-

Free design

-

Flexible delivery

-

Business Guidance

experienced

Best for growing brands-

2000+ pieces (average)

-

Sample shipped in 3 days

-

Free design

-

Business Guidance

-

On-time delivery

-

Cheaper quote

-

Hot Selling Recommend

Brand owner

Ideal for large-scale brands-

5000+ pieces (average)

-

Custom sample

-

Market insights

-

New product development

-

Exclusive authorization

-

Exclusive production line

-

VIP Team service

-

Lowest price quote